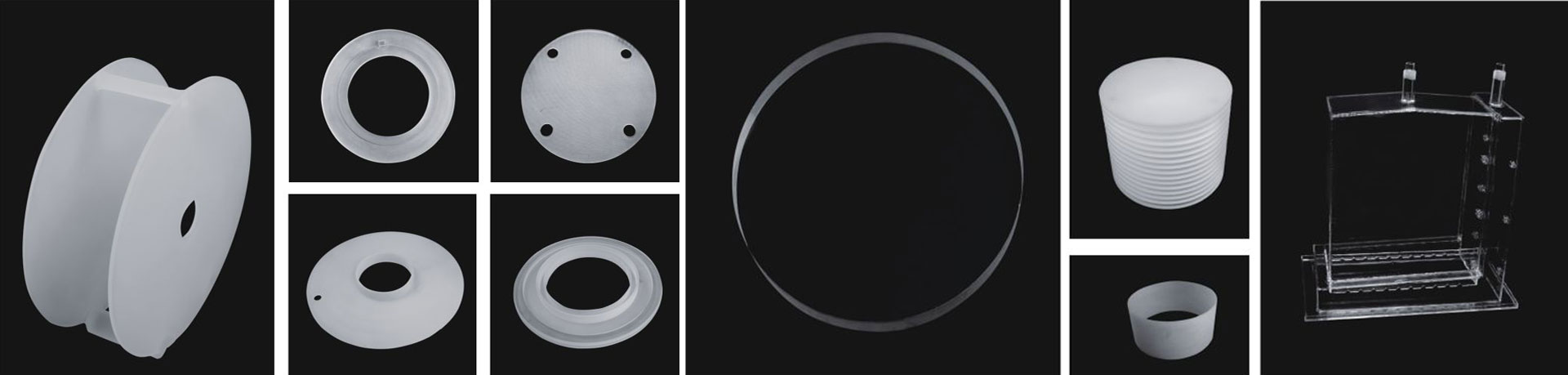

- Feiguan Quartz Glass Company specializes in the research, development, production and sales of quartz glass products. The company has advanced production equipment and technology and is committed to providing high-quality quartz glass products to meet the needs of different fields.

- We offer manufacturing products ranging from simple glassware to complex quartz equipment and supply to semiconductor, optical fiber, analysis , solar, water sterilization and lighting industries, as well as smaller universities and development laboratories.。

Quartz glass properties

- Excellent heat resistance: Quartz glass has a softening point temperature of approximately 1730°C, which allows it to be used for long periods of time in environments up to 1100°C, and can even withstand temperatures as high as 1450°C for short periods of time. This outstanding high temperature resistance makes quartz glass uniquely suited to application scenarios where extreme temperatures need to be withstood.

- Strong chemical stability: quartz glass is extremely resistant to corrosion, and it reacts with virtually no acids other than hydrofluoric acid. Its acid corrosion resistance far exceeds that of acid-resistant ceramics and stainless steel, especially in high-temperature environments, where this chemical stability is particularly prominent. This makes quartz glass in the chemical, pharmaceutical and other industries that need to resist the erosion of chemical substances have a wide range of applications.

- Outstanding Thermal Stability: Quartz glass has an extremely low coefficient of thermal expansion, which means it can withstand drastic temperature changes without breaking or deforming easily. Even when heated to approximately 1100°C and then quickly placed in room temperature water, quartz glass will not burst, a characteristic that makes it stable at high temperatures and in alternating hot and cold environments.

- Excellent optical properties: quartz glass has good light transmission properties in the entire spectral band from ultraviolet to infrared, which makes it widely used in the field of optoelectronics. Whether it is used as a basic material for optical instruments or for manufacturing windows and lenses with high light transmission, quartz glass can bring its unique advantages into play.

- Excellent electrical insulation performance: quartz glass has an extremely high resistance value, equivalent to 10,000 times that of ordinary glass, which makes it an excellent electrical insulation material. Even at high temperatures, quartz glass maintains good electrical properties, so it has a wide range of applications in the power and electronics industries.

- Excellent heat resistance: Quartz glass has a softening point temperature of approximately 1730°C, which allows it to be used for long periods of time in environments up to 1100°C, and can even withstand temperatures as high as 1450°C for short periods of time. This outstanding high temperature resistance makes quartz glass uniquely suited to application scenarios where extreme temperatures need to be withstood.

- Strong chemical stability: quartz glass is extremely resistant to corrosion, and it reacts with virtually no acids other than hydrofluoric acid. Its acid corrosion resistance far exceeds that of acid-resistant ceramics and stainless steel, especially in high-temperature environments, where this chemical stability is particularly prominent. This makes quartz glass in the chemical, pharmaceutical and other industries that need to resist the erosion of chemical substances have a wide range of applications.

- Outstanding Thermal Stability: Quartz glass has an extremely low coefficient of thermal expansion, which means it can withstand drastic temperature changes without breaking or deforming easily. Even when heated to approximately 1100°C and then quickly placed in room temperature water, quartz glass will not burst, a characteristic that makes it stable at high temperatures and in alternating hot and cold environments.

- Excellent optical properties: quartz glass has good light transmission properties in the entire spectral band from ultraviolet to infrared, which makes it widely used in the field of optoelectronics. Whether it is used as a basic material for optical instruments or for manufacturing windows and lenses with high light transmission, quartz glass can bring its unique advantages into play.

- Excellent electrical insulation performance: quartz glass has an extremely high resistance value, equivalent to 10,000 times that of ordinary glass, which makes it an excellent electrical insulation material. Even at high temperatures, quartz glass maintains good electrical properties, so it has a wide range of applications in the power and electronics industries.

A collection of experts active on the front lines of the quartz processing industry! We have been able to start production, quality improvement and a stable supply of products as soon as an order is received.

- This processing technique requires technicians with superior manual skills to create quartz products with complex shapes or high precision requirements by means of blowing and soldering. The following are some of the key features of fire processing:

- Fuel: Fire treating uses hydrogen and oxygen as fuel because their mixture can generate very high temperatures, enough to soften quartz glass and make it easy to shape.

- Manual Handling: Fire treatment requires manual handling by technicians, which requires skill and experience to ensure product quality and safety.

- Applicability: Fire treatment is suitable for products with complex shapes or high precision requirements, which are often difficult to produce by mechanized or automated means.

- Product Characterization: Quartz products manufactured through fire treatment typically have better physical and chemical stability and are able to withstand extreme temperature changes and chemical corrosion.

CNC control system capable of multi-axis linkage for complex quartz glass processing tasks

CNC machining of quartz glass is a method of precision machining of quartz glass using computer numerical control (CNC) technology. This type of machining enables high precision machining of complex geometries such as curved surfaces, beveled surfaces, grooved areas, spherical surfaces, cylindrical surfaces, apertures, taper angles, etc. CNC machining is characterized by a high degree of automation, whereby the raw material is engraved, cut and molded into the desired shape by precisely controlling the movement of the tools. the precision and repeatability of this method is very high, and it is particularly suited to the manufacture of components that require a high degree of precision and Complex geometries